Flashing of RoofWall Intersections in Existing Homes Building America Solution Center

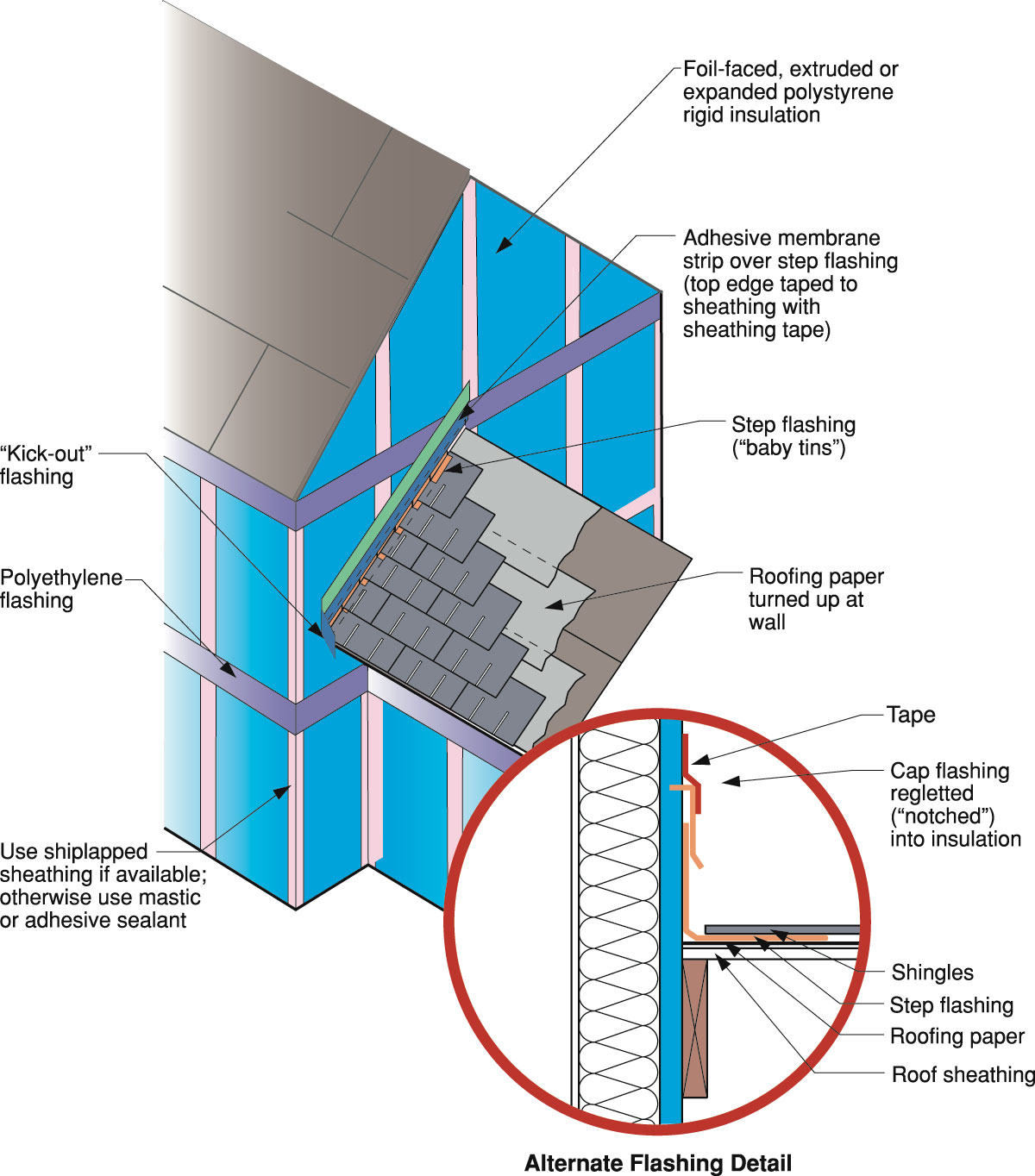

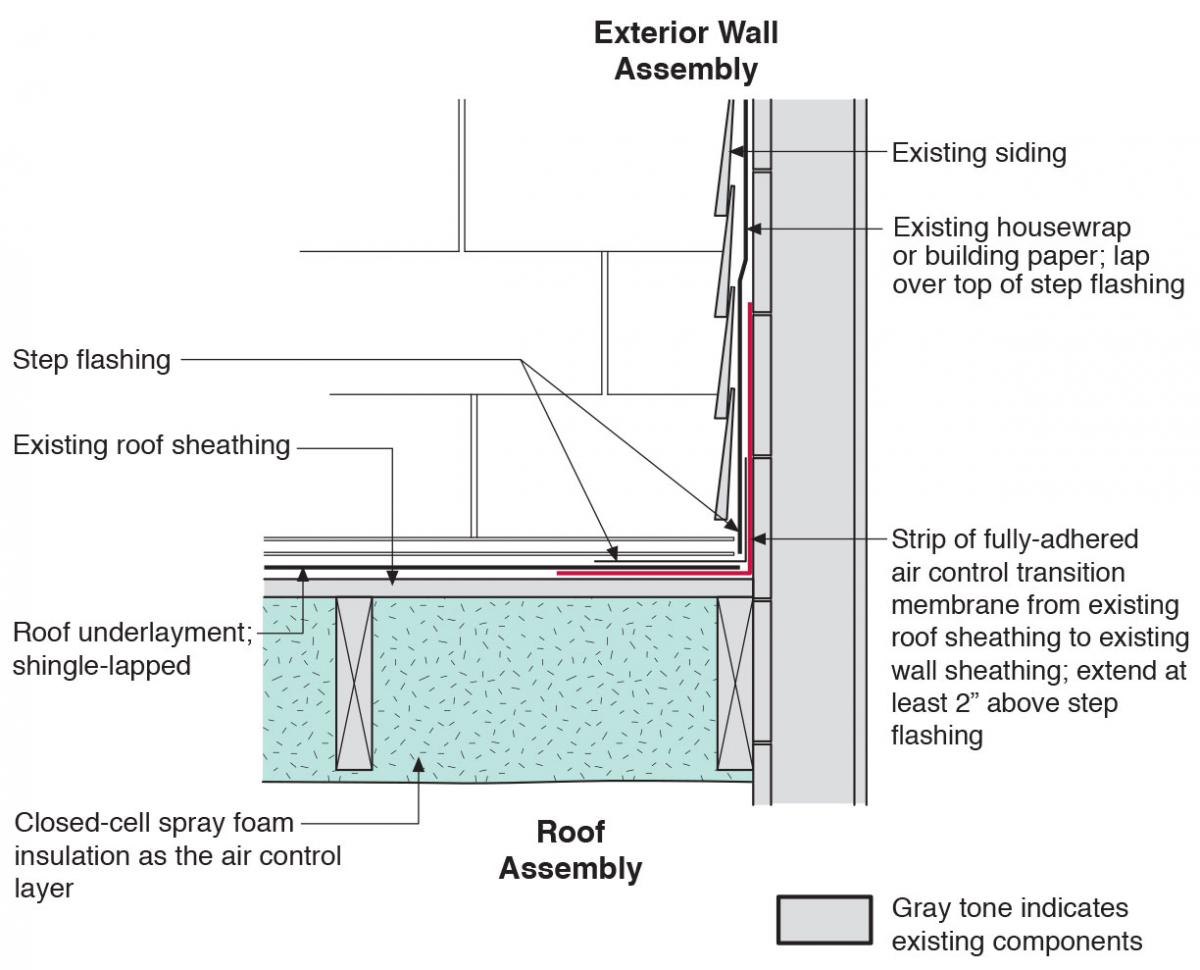

Install a new adhesive membrane (ice and water protector) and metal step or continuous flashing that is properly integrated into the weather-resistant barrier and wall and roof coverings to provide continuous water, air, vapor, and thermal control layers on the walls and roof.

Flash a roof

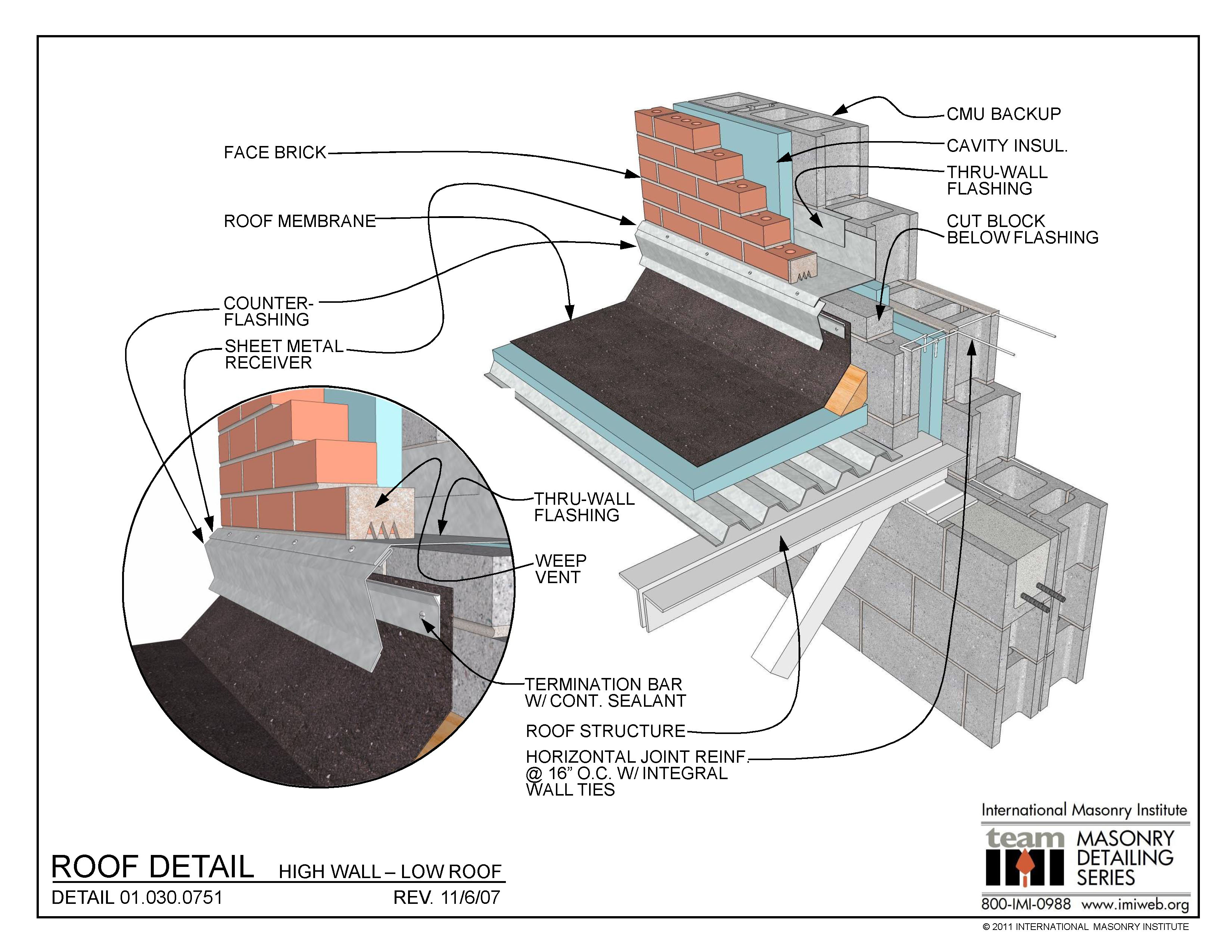

Roof to Wall Flashing: Why Details Matter for Single-ply Roofing Systems. Roof to wall flashing is critical to the performance of every single-ply roofing system. These transition points, where the flat part of the roofing system is tied into the parapet wall, are potentially vulnerable areas for water intrusion.

Roof flashing Building Inspections Brisbane QBIS

1 2 3 4 5 6 7 8 9 Share 3.1K views 2 years ago How to tape roof valleys, T-joints and vented ridges A critical detail for water intrusion management, the transition from a roof to a wall.

Roof flashings BRANZ Build

Tips on Installing Roll, Step and Roof-To-Wall Flashing Photo: Atlas Roofing Corporation Flashing plays a critical role in shielding a roof from water damage. Essential for leak-proof performance, flashing protects intersections of the roof plane and penetrations through the roof surface.

InterNACHI Inspection Graphics Library Exterior » Wood siding » roofflashing.jpg

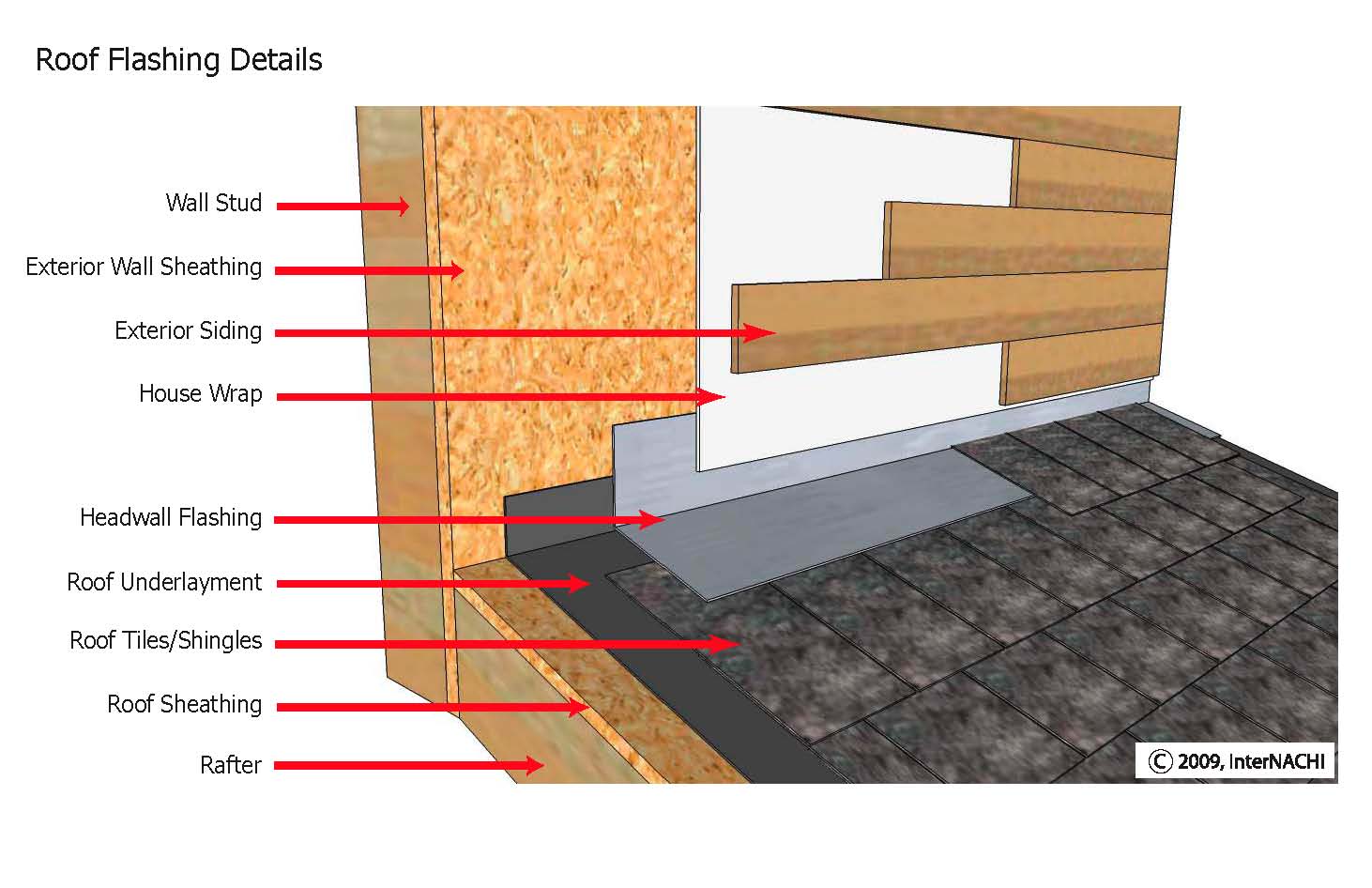

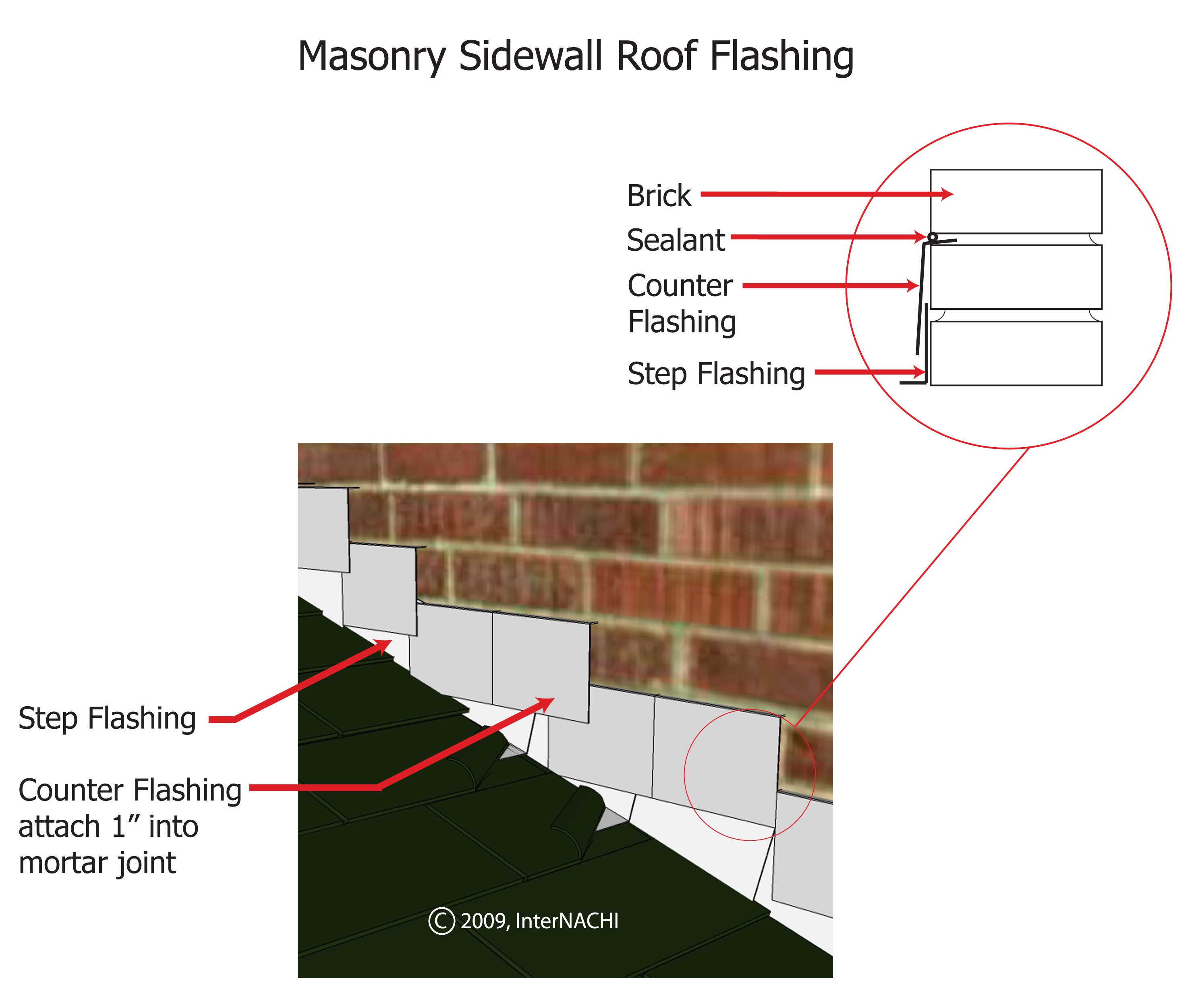

The flashing needs to be installed before installing the roof shingles. The metal flashing is formed with a hook edge and cleated on 12" centers. The flashing extends up the wall at least 4". The flashing extends onto the roof a minimum of 2 inches - 4 inches is preferable in more severe climate areas. Flashing joints are lapped 6" in the.

LowSlope Roof ThroughWall Flashing (BUR) Inspection Gallery InterNACHI®

Scope. Install step and kick-out flashing at all roof-wall intersections to protect walls from water intrusion, and install boot or collar flashing at all roof penetrations to protect roofs from leaks. Install corrosion-resistant flashing pieces that are overlapped in a shingle fashion. Extend step flashing at least 4 inches up the wall from.

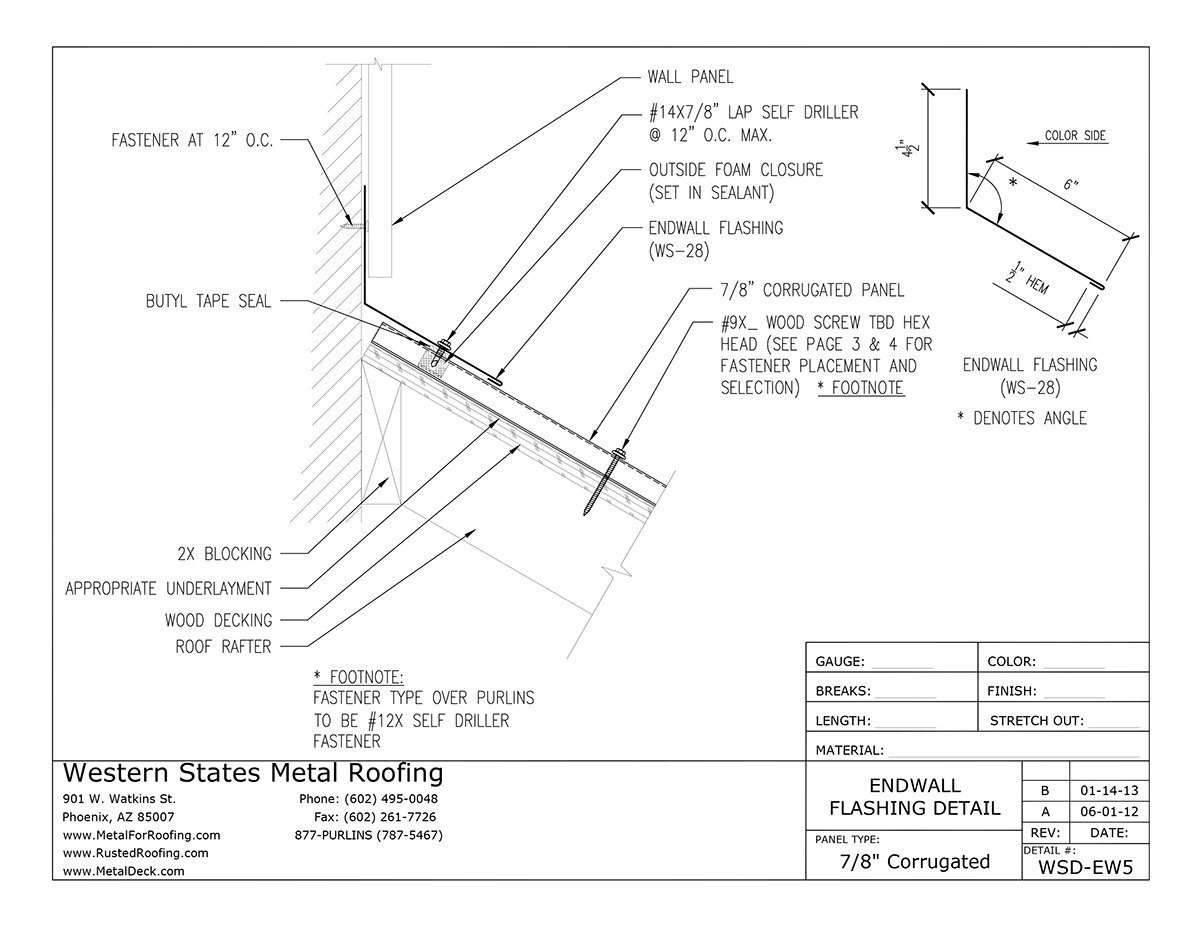

Part WS28 Endwall Flashing for Corrugated Metal Roofing

Since the risk of failure and cost of repair at roof-to-wall details is sky high (pun intended), some designers and contractors prefer to install two layers of flashing to ensure durable performance to hopefully eliminate call-backs. On some jobs we have seen stainless steel flashing and adhesive membrane flashing work together to provide.

Flashing of RoofWall Intersections in Existing Homes Building America Solution Center

VYCOR® Plus self-adhered flashing installation. VYCOR® Plus provides superior protection against water, air and moisture infiltration in window and door openings, corner boards, under stucco finishes, masonry walls and other flashing areas. VYCOR® Plus is a self-adhered flashing ideal for sealing joints, seams, holes, and other unwanted.

True ThroughWall Flashing for Brick Veneer JLC Online

Roof flashing is typically a thin metal material fabricated from rust-resistant metal, such as G-90 galvanized steel, a frequently used flashing material, copper, or aluminum. Depending on the company, flashing may even be available in lead or zinc alloy.

Roof flashings BRANZ Build

Roof Area Divider 9.2. Counterflashing Description: Copper flashing is used wherever a wall intersects a roof. Such a system usually consists of copper counterflashing and base flashing in conjunction with roof composition flashing or coping.

Pin on Roof

Roof to Wall Flashing . There have always been problems with roof to wall flashing details at Head Walls, Rake (Side) Walls, and Chimneys where the Roof Coverings intersect with the Exterior Wall Covering - especially if stucco, brick, or stone veneer are used.. All exterior wall coverings, whether it is wood siding, vinyl siding, brick or stone veneer, stucco, etc. must be kept up off the.

Endwall Flashing Installation On A Metal Roof. EASY Installation Video Wall Flashing On Metal

Wall flashings are required at openings, corners, intersections, and wherever a roof terminates into a wall. While peel-and-stick tapes have replaced these flashings at many details, metal flashings are still preferred for many standard details and applications where the flashing is visible or needs to hold a shape or serve as a drip edge.

01.030.0751 Roof Detail High Wall Low Roof International Masonry Institute

Step Flashing where a roof meets a wall Mr. Kongable 89K views 3 years ago Low-Slope Roof Self-Adhered Base Sheet Installation | How to install Self-adhered Membranes Polyglass USA Inc

Headwall Flashing Inspection Gallery InterNACHI®

High Wall Flashing with 10-ft. Wide Sheets In detail 317A, Dave reviews the steps for high wall flashing using 10-ft. sheets. The steps are similar to those of 317C: a base layer of EnergyGuard polyiso and then a layer of reinforced membrane, attached using fasteners and plates.

InterNACHI Inspection Graphics Library Roofing » Flashing » masonrysidewallroofflashing.jpg

Roof Coating 100 Roof Assembly Detail Download Single-Ply 150 Walkway Pads Detail Download Single-Ply 214 Gutter Edge Detail Download

Roofing Details That Work JLC Online

Correct detailing of LYSAGHT®roof and wall flashing has more than cosmetic importance - it is essential in ensuring the wet weather performance of the cladding. Correct flashing and detailing will improve the overall appearance of the finished job.